For an accurate thermal design, please provide:

Process-fluid and any contaminants

Allowable pressure drop

Preferred tube or fin materials

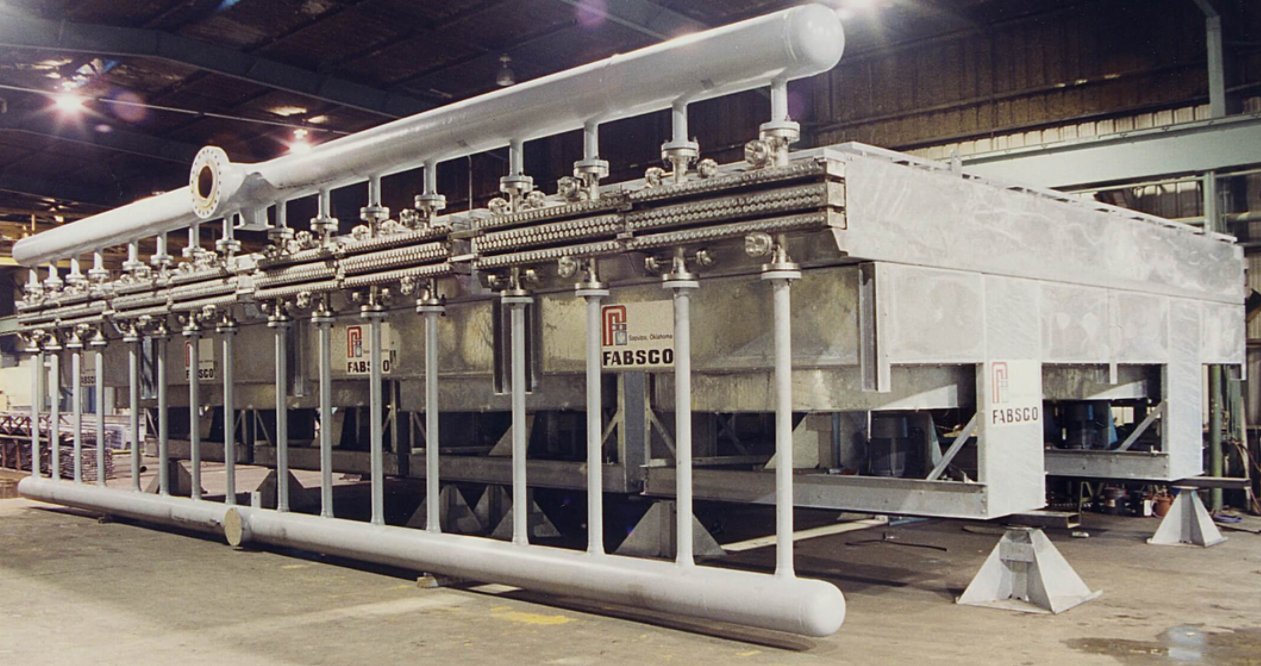

Air-cooled Heat Exchangers

Fabsco air-cooled heat exchangers (ACHX) use ambient air to pull heat from a liquid or gas stream. These exchangers can be either horizontally or vertically configured, with either forced or induced draft air. ACHX requires no cooling water, and operational costs are lower than other types of exchangers.

Applications & Industries Served

Fabsco air cooled heat exchangers are primarily used in several applications, including

LNG pre‑treatment

Natural‑gas‑liquid (NGL) cryogenic processing

TEG dehydration & condensate re‑boil

Amine treating / H₂S removal

Gas‑compression after‑coolers (up‑stream)

Mid‑stream gas‑plant cooling

Refinery & petrochemical bundle retrofits (down‑stream)

Power generation & industrial refrigeration

Why Choose Air‑Cooled Heat Exchangers?

Zero water use – no chemical treatment or blow‑down.

Lower operating expenses compared with shell‑and‑tube or evaporative systems.

Quick‑turn spare parts and bundle replacements, supported by a dedicated aftermarket team.

Field‑friendly maintenance—fans, drives, bundles, and other components are designed for straightforward replacement.

Need a niche solution? Fabsco’s engineering team routinely re‑rates or re‑tubes bundles for geothermal, carbon‑capture and flare‑gas recovery projects.

Spare Parts and Service

Fabsco’s Aftermarket Parts and Service Team stands ready to meet your cooler needs. They can provide "quick turn" replacement parts, or bundles, assistance on start-up and trouble-shoot competitor's coolers. We regularly supply fans, blades, plugs, belts and other critical parts for our units and others in the field.

The following is a partial list of Fabsco Fin Air - Field Services:

Tube leak detection

Bundle hydrostatic testing

Bundle Helium Testing

Bundle re-rate, with "R" stamp

Bundle re-tube (in Fabsco facility)

Fan replacement

Fan component replacement (blades, hub, mounts, bushings, etc.)

Fan blade adjustment

Fan airflow measurement

Fan amperage draw

Flange re-facing

Vibration testing per API 661

Bearing replacement

Shaft replacement

Sheave replacement

Drive alignment

Drive revision, increasing HP and airflow

Start up supervision

Field Erection supervision

Fan and Drive inspection

Actuator replacement

Louver replacemetn

Bugscreens

Recirc system retro-fit

Cooler refurbishment