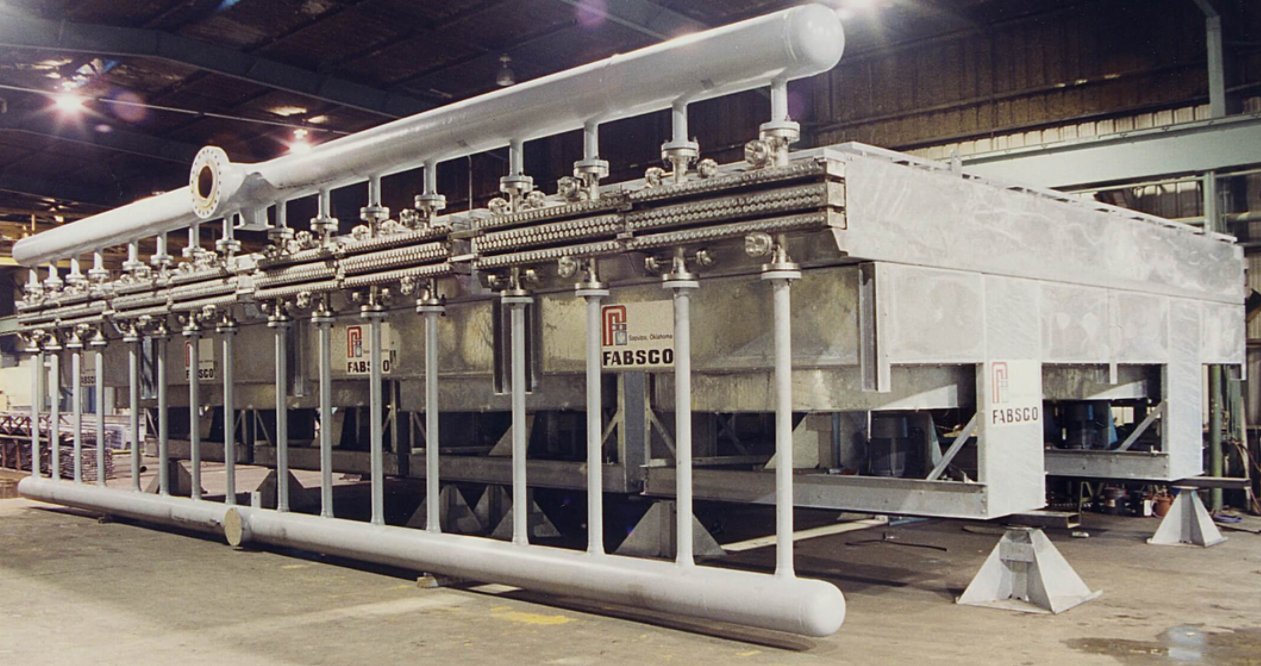

Air-cooled Heat Exchangers

Fabsco air cooled heat exchangers (ACHX) are exchangers that use ambient air to pull heat from a liquid or gas stream. These exchangers can be either horizontal or vertically configured, with either forced or induced draft air. ACHX require no cooling water, and operational costs are lower than other types of exchangers.

Air cooled heat exchangers are primarily used in several applications, including:

Condensing

Gas compression

Petrochemical

Petroleum refining

Power generation

Refrigeration

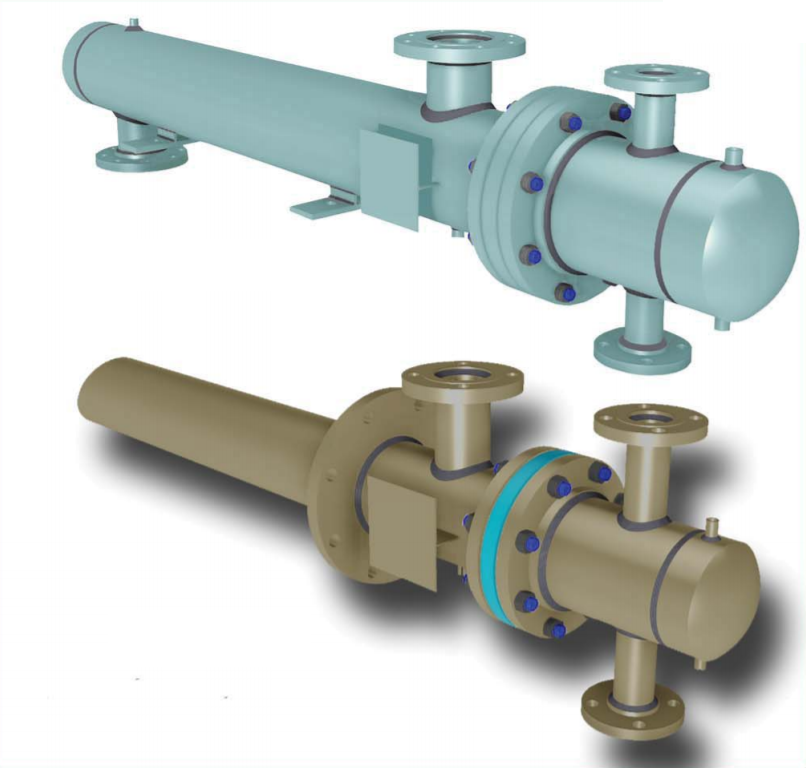

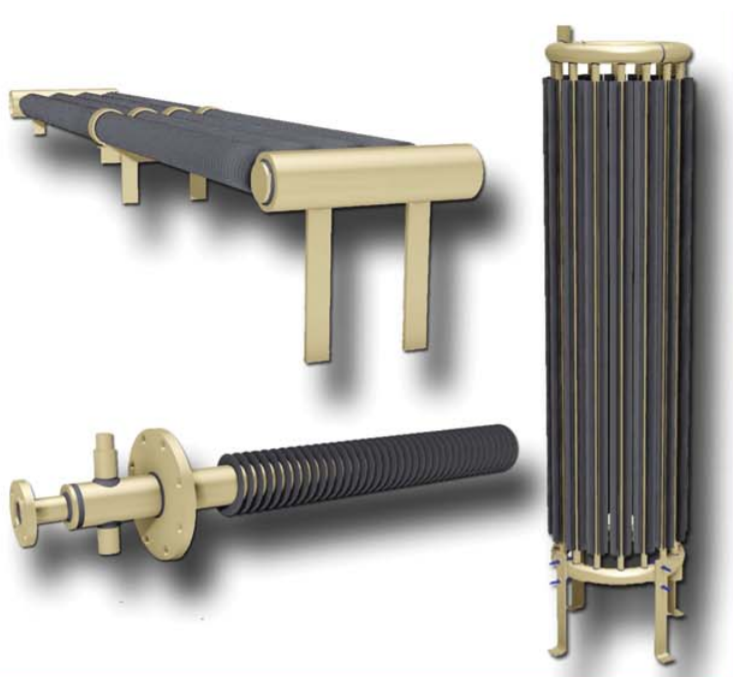

Shell & Tube Heat Exchangers

Shell and tube heat exchangers are the most common type of heat exchanger in oil refineries and other large chemical processes, and are well suited for high pressure applications. As its name implies, they consist of a shell (large pressure vessel) with a bundle of tubes inside it. One fluid runs through the tubes, while another fluid runs around the tubes to transfer heat between the two. The set of tubes is called the tube bundle, and may be composed of either bare or finned tubes. Fabsco manufactures shell and tube exchangers in various configurations, including U-tube and straight tube designs, single or multi-pass, and single or dual phase.

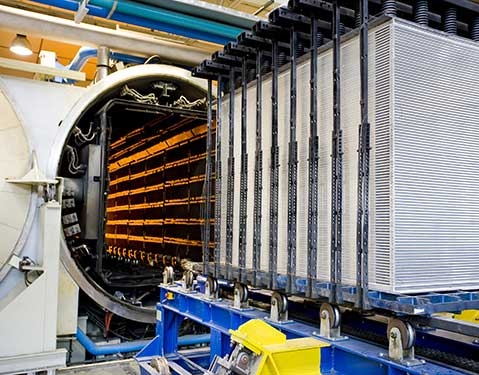

Brazed Aluminum Heat Exchangers

Fives has manufactured more than 10,000 brazed aluminum heat exchangers (BAHX) since 1959. BAHX's offer several advantages over conventional exchangers:

Compact: 4-5x less surface area per volume

Lighter weight

Improved behavior under cryogenic temperatures

Larger temperature gradients from warm end to cold end

High and low pressure streams can be in the same exchanger

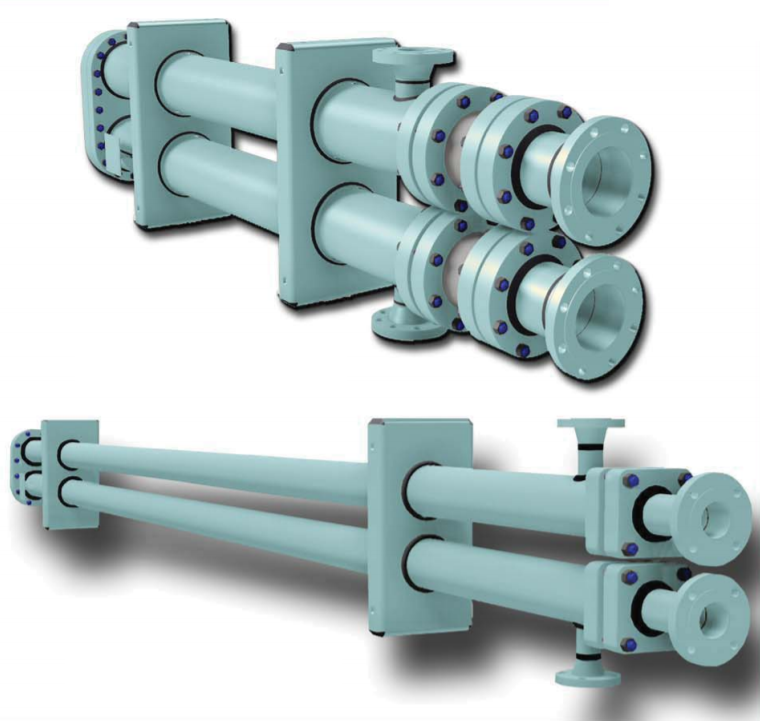

Hairpin Shell and Tube Heat Exchangers

R. W. Holland has been manufacturing hairpin shell and tube heat exchangers since the 1970's. This style of heat exchanger offers several advantages over conventional exchangers:

Operates in true counter current flow, permitting extreme temperature cross

Economically adaptable to service differentials

Ideal for wide temperature ranges and differentials

Standard double pipe or multi-tube design reduces engineering, thermal design, drafting and shop fabrication costs

Cold Boxes

A Fives cold box includes one or more integrated brazed aluminum heat exchanger(s) in a carbon steel casing. These cold boxes combine brazed heat exchangers with any type of complementary cryogenic equipment, such as:

Knock-out drums

Two-phase injection drums

Distillation columns

Interconnecting piping

Valves and instrumentation