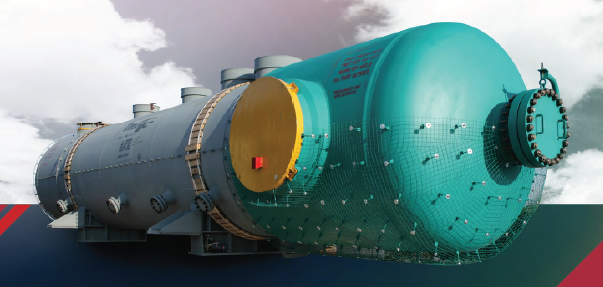

Process Gas and Waste Heat Recovery Boilers

The typical applications of an OCS WHR or PG Boiler is inside oil refineries, sulphur removal facilities, ammonia plants, hydrogen plants, methanol plants, styrene, sulphuric acid plants, claus plants, coal gasification, partial oxidation, nitric acid, caprolactam and formaldehyde production plants where it is necessary to quench the very hot process gas. OCS strengths include engineering capability in house, supplying personalized solutions built on clients specifications, in-house fabrication and assembly.

OCS staff is able to manage process and thermal design of:

Waste Heat Recovery Boilers for Claus

Unit and Tail Gas System Incinerators

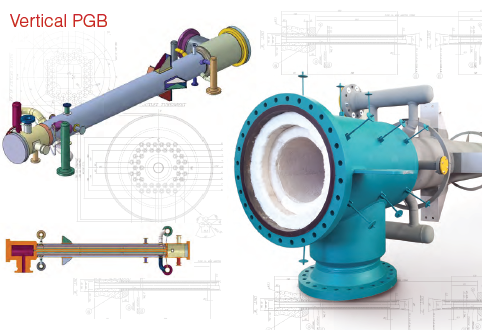

Process Gas Boilers for Reformers

Steam Drums

Columns and Towers

O.C.S. designs and manufactures Heavy-Duty Columns and Towers for a variety of applications within the Oil, Gas, and Power industries.

Their fabrication experience covers carbon steel, low alloy steel, nickel alloys, stainless steel, cladded materials and aluminum. OCS units have been shipped worldwide including to the United States, Europe, Asia, the Middle East, and South America.

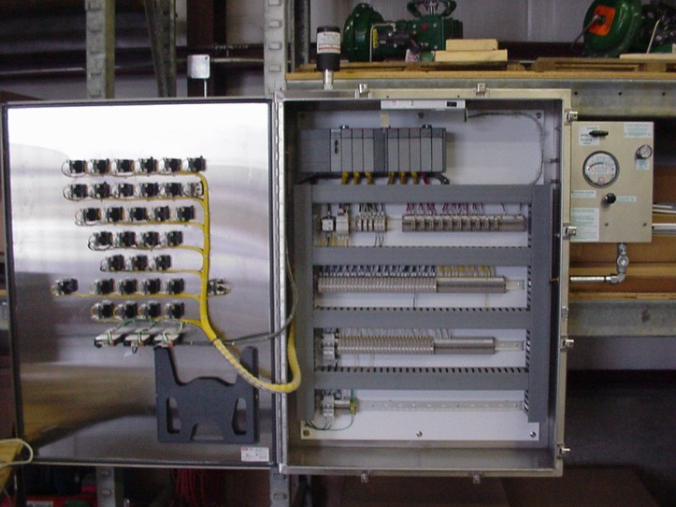

Custom Automation and Control Packages

ICC is an approved manufacturer of control panels and assemblies for use in hazardous locations.

They are one of only two Crouse Hinds Tier III modification shops in the United States

They are qualified system integrators for Allen Bradley, Honeywell LX, and Siemens

Their quality management system is certified to ISO 9001 standards.

ICC is certified to design and build equipment with ASME U and S stamps. They have AWS D1.1 and PED certified welders and their engineering and manufacturing processes are certified to ATEX, IEC, UL, and CSA